Fusibility of glazes, ceramic bodies, hashes

Fusibility analysis can be carried out thanks to the heating microscope, which allows the direct observation of materials behaviour during a heating cycle. This technique can be applied to direct characterization of glazes, glasses, powders for continuous casting, coal, slag, ashes, etc…

The new generation heating microscopes allow to analyze the behaviour of materials during a fast heat treatment thanks to a computerised image analysis.The system software automatically analyses the sample images acquired during the test at predetermined temperature or time intervals.

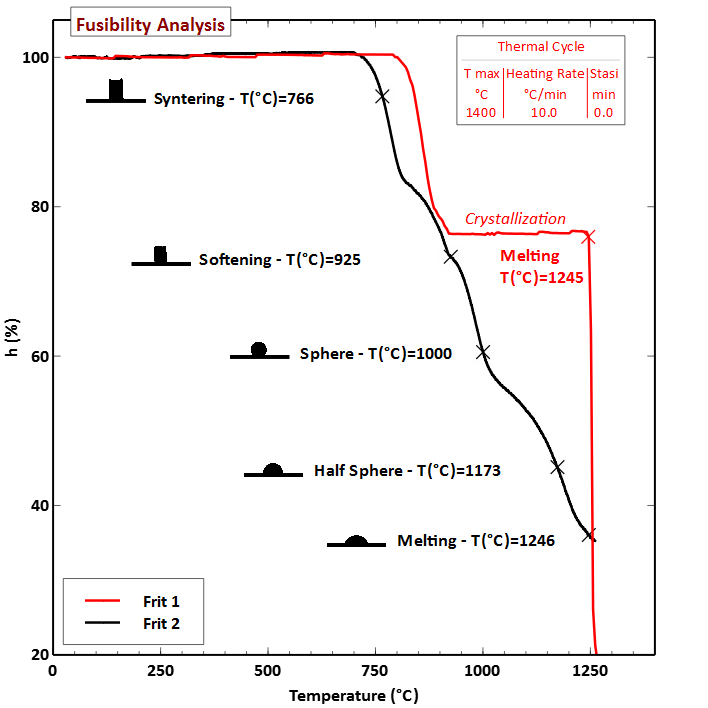

Thanks to calculations using geometrical parameters of the test piece (height, width, contact angle), it is able to identify specific shapes assumed by the sample during the heating process, such as: Deformation (Softening), Sphere, Hemisphere and Flow (Melting) Temperatures.

Comparing two ceramic glazes at 50°C/min heating rate

The black curve represents the behaviour of a vitreous frit: as the temperature increases, the sample passess through the characteristic shapes of glasses (sintering, softening, sphere, half-sphere, melting). The red curve, insted describes the behaviour of a crystallizing frit. After the sintering phase, between 900°C and 1250°C, the curve shows a plateau: here happens the crystallization of the material. As a consequence, when the temperature increases, the sample will no longer behave like a glass, but melts abruptly as a crystalline material.

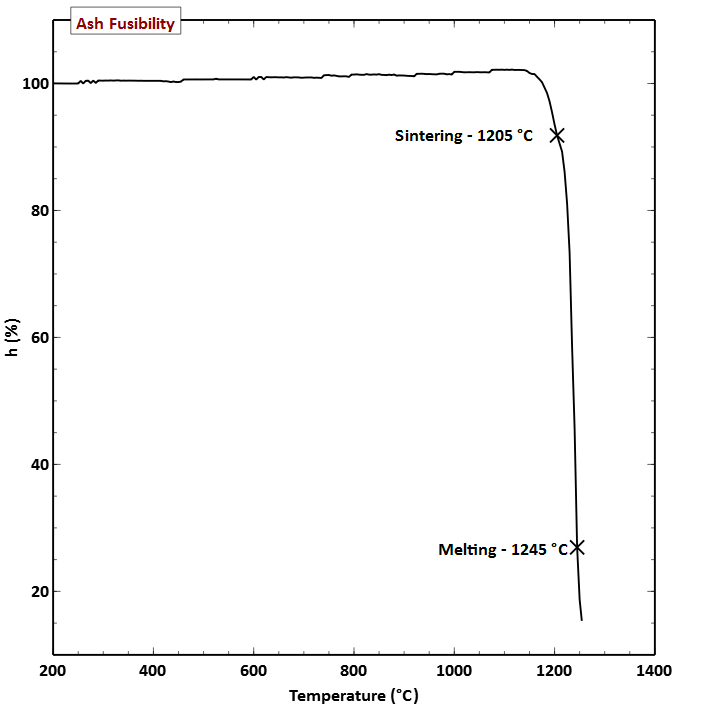

Hash fusibility study